Product Design

- Home

- Capabilities

- Product Design

Turnkey Product Design

Comprehensive Part Design

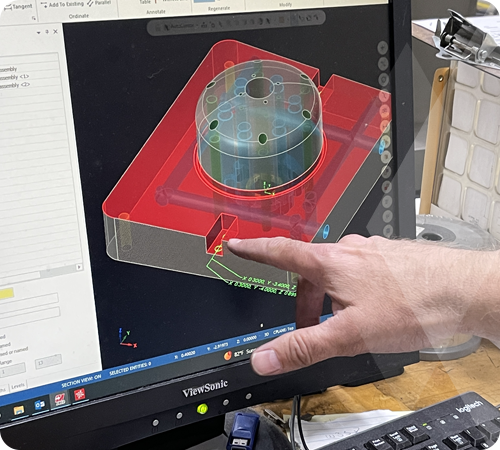

- The Flambeau Team has many tools available to review and support part design development. Our experienced and knowledgeable designers can support SolidWorks, NX, Pro/ENGINEER and CATIA. Reviewing details with mold-flow and FEA analysis up front saves our customer time and money.

- Our staff of engineers is experienced at giving hands-on support from conception through production to ensure robust part designs and manufacturing processes. Prototyping – We have the capability to validate part design using our in-house 3-D printing equipment.

The Right Material

- A thorough and accurate part design along with the right material for the application are inseparable. Our team will work with you and our staff of material specialists have the technical and material expertise to ensure we are delivering the optimized material for your application.

Optimized Mold Design

- Flambeau is unique in its ability to provide in-house mold building capabilities. We provide high quality tooling made in America and a strong knowledge base to support optimal mold design. For those looking for off-shore tooling, Flambeau leverages a network of international mold-building resources. Full CAD-CAM design and tool-build capabilities, mold-flow analysis tool-build optimization.

Scientific Molding Process

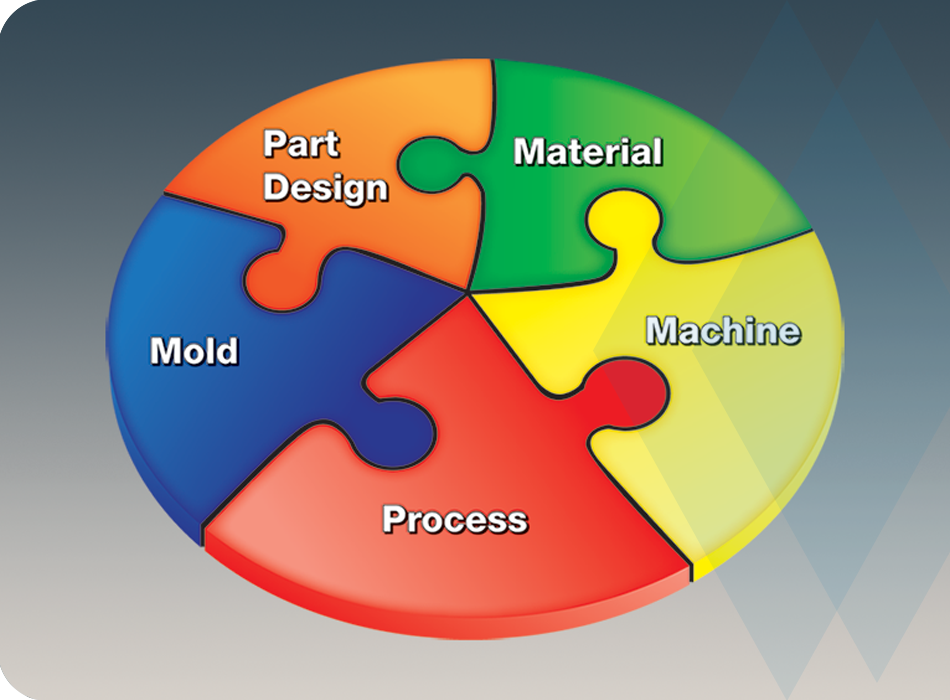

- Flambeau’s Injection Molding utilizes Scientific Molding and RJG E-Dart technology to implement successful molding processes focused on the four cornerstones of injection molding: Part Design, Material, Mold Design, and Process.

- Implementing this successfully has been and continues to be a focused effort utilizing key molding variables to optimize part quality and cycle time for our customers.

Machine

- The machine must be “statistically capable”. It must be maintained in accordance with OEM specifications in order to provide valid data and to develop a durable molding process for each mold it runs.

Tech Reports

Benefits of Diversification – Medical Flambeau Medical Markets Group is in a unique position to fulfill your medical component requirements. Flambeau represents three quarters of a century of built-up accumulated expertise in thermoplastic molding. Customers experience for themselves the breadth and depth of knowledge acquired by the people of Flambeau when deployed on their project. […]

PACCAR® DEF Tank Diesel Exhaust Fluid (DEF) is a liquid used to reduce the amount of air pollution created by a diesel engine. Flambeau customer, PACCAR, needed a new back-of-cab DEF tank assembly for two of the company’s Kenworth® diesel heavy-duty trucks. With a successful air duct manufacturing project for PACCAR winding down, the company […]

3D Scanning Flambeau utilizes the latest technologies in order to provide its customers with high quality, precisely engineered products. Engineers with Flambeau Technology Center (FTC) in Baraboo, Wisconsin, utilize a state-of-the-art 3D scanner by Hexagon® Manufacturing Intelligence that assists Flambeau in maintaining its high standards of excellence for its products and services. The RS6 scanner […]

Our Work in Action

Our Engineering and Manufacturing Projects

Automotive Fuel Tanks

HVAC Air Ducts

Septic Tanks

tanks designed to meet specific environmental regulations and customer requirements…