Tooling (Design + Fabrication)

- Home

- Capabilities

- Tooling (Design + Fabrication)

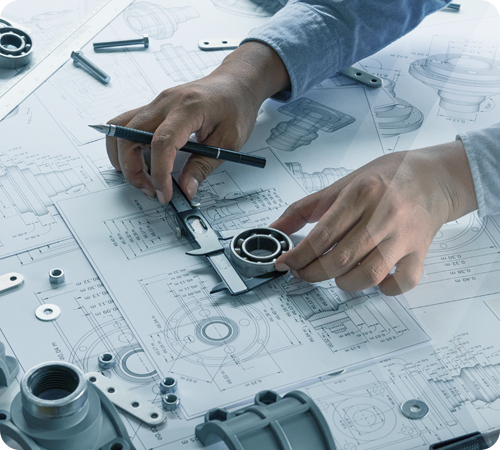

Tool Design Manufacturing Capabilities

You gain a competitive edge from our experience and resources. Our fifty years of experience designing and building molds for Flambeau has prepared us for your most challenging projects. Precision molds are delivered on time, including molds for highly engineered products. When product and tool design are concurrent, your tools are ready up to one-third faster.

- Expertise in both the design and construction of injection and extrusion blow molding

- 11 CAD workstations (Unigraphics, SolidWorks, CATIA and PRO-E)

- Surface/solids capabilities

- Expertise in automation and runnerless molds

- Internet based electronic file transfer, 24 hours a day

- Offers tooling options for prototyping

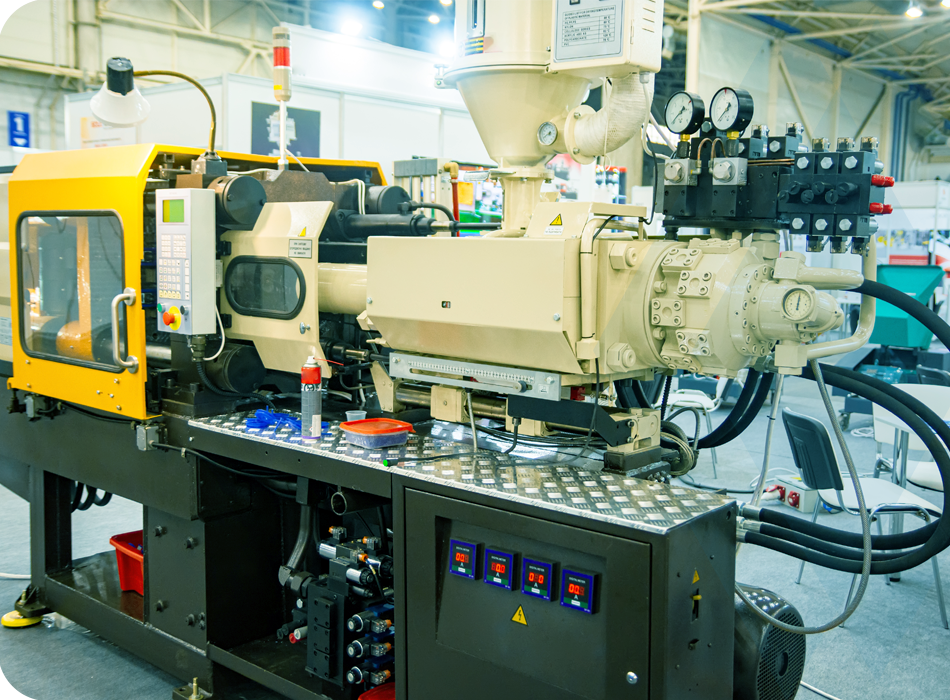

Precision Tool Construction

- Running two shifts of operations

- Certified tooling with pre-production molded samples

- Alliances with off-shore and domestic tooling resources

CNC Capabilities

- EDM (wire and sinker capabilities)

- Shop floor tool path programming (2D & 3D)

- Around-the-clock unattended operations

- 3 and 5 axis CNC machining centers

- Precision injection molds sized to run in 15-1,700 ton machines

- Extrusion blow molds sized to run in presses from 1 to 35 pound shots

Flambeau’s Engineering Services

Our 70+ years of experience allows us to optimize the design and construction of the blow and injection molds. Engineering Services include:

- Product Design – Engineering and Design Support

- On-site design or engineering support as desired

- Design for manufacturability consulting services

- Customized product testing and process validation control

- Project Management – PMGS (Project Management Gate System) APQP driven

- Turnkey solutions

- EPA regulatory compliance and certification

- Prototype and Production Tooling

- Fabrication of Secondary Automated Equipment & Robotics

- CMM Capabilities

Mold Quotation Request Form

If you’d like to receive a quote on mold manufacturing, fill out the form below. A Flambeau representative will contact you with more details.

Fields marked with an asterisk (*) are required.

Tech Reports

Benefits of Diversification – Medical Flambeau Medical Markets Group is in a unique position to fulfill your medical component requirements. Flambeau represents three quarters of a century of built-up accumulated expertise in thermoplastic molding. Customers experience for themselves the breadth and depth of knowledge acquired by the people of Flambeau when deployed on their project. […]

PACCAR® DEF Tank Diesel Exhaust Fluid (DEF) is a liquid used to reduce the amount of air pollution created by a diesel engine. Flambeau customer, PACCAR, needed a new back-of-cab DEF tank assembly for two of the company’s Kenworth® diesel heavy-duty trucks. With a successful air duct manufacturing project for PACCAR winding down, the company […]

3D Scanning Flambeau utilizes the latest technologies in order to provide its customers with high quality, precisely engineered products. Engineers with Flambeau Technology Center (FTC) in Baraboo, Wisconsin, utilize a state-of-the-art 3D scanner by Hexagon® Manufacturing Intelligence that assists Flambeau in maintaining its high standards of excellence for its products and services. The RS6 scanner […]

Our Work in Action

Our Engineering and Manufacturing Projects

Automotive Fuel Tanks

HVAC Air Ducts

Septic Tanks

tanks designed to meet specific environmental regulations and customer requirements…