Secondary Operations

- Home

- Capabilities

- Secondary Operations

Secondary Operations Capabilities

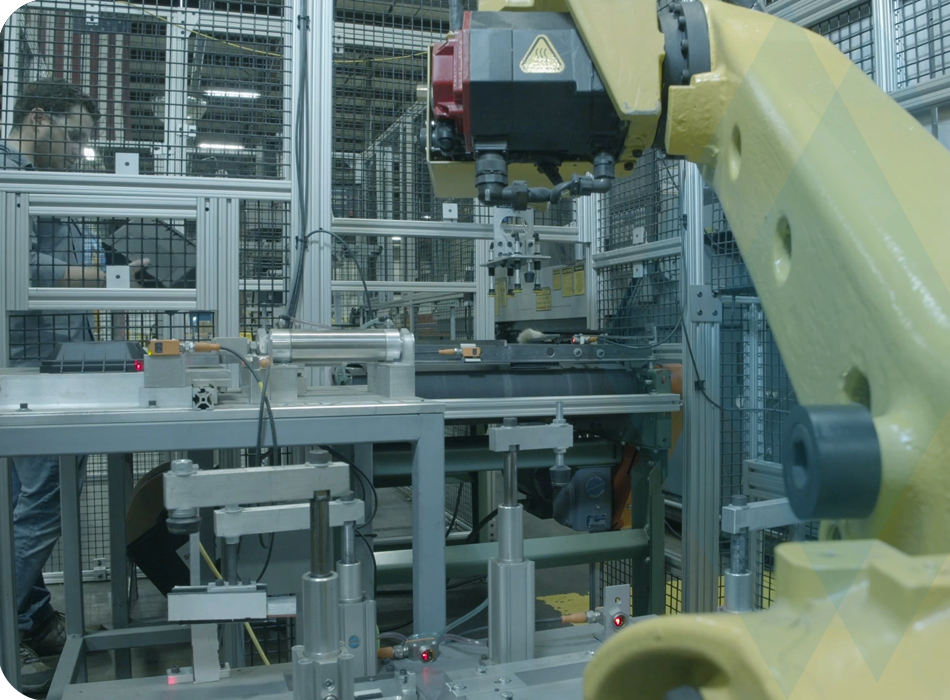

From concept to the finished product, we can customize work cells to fit your requirements. This capability, coupled with Flambeau’s engineering services and manufacturing capabilities, provide our customers a complete “turnkey” option for their most challenging projects.

Flambeau designs work cell environments that are customized to fit the specific needs and requirements of every customer/product, providing value as well as a competitive advantage.

Secondary / Custom

Capabilities:

- Complex / Product Assembly – Manual, Semi-Automatic, Automatic Custom Packaging and Custom Packaging Including POP Display

- Inserting, Cutting, Slitting, Routing, Robotic Routing, Drilling, Reaming, Facing, Punching, De-gating, Fastening, Stapling, Riveting, Crimping and Vacuum Metalizing

- Custom Post-Mold Assembly

- Bonding and Welding: Melt Welding/Hot Plate Bonding, Infrared Welding, Welding, Heat Staking, Spin Welding, Ultrasonic Welding, Ultrasonic and Heat Thread Insert Installation, and Vibration Welding

- Decorating: Hot Stamping, Pad Printing, Silk Screening, SpectraMolding™ In-Mold Labeling / Graphics — Including fabrics and carpeting, Post Mold Decorating Including Painting and Printing, and Heat Transfer

Tech Reports

Benefits of Diversification – Medical Flambeau Medical Markets Group is in a unique position to fulfill your medical component requirements. Flambeau represents three quarters of a century of built-up accumulated expertise in thermoplastic molding. Customers experience for themselves the breadth and depth of knowledge acquired by the people of Flambeau when deployed on their project. […]

PACCAR® DEF Tank Diesel Exhaust Fluid (DEF) is a liquid used to reduce the amount of air pollution created by a diesel engine. Flambeau customer, PACCAR, needed a new back-of-cab DEF tank assembly for two of the company’s Kenworth® diesel heavy-duty trucks. With a successful air duct manufacturing project for PACCAR winding down, the company […]

3D Scanning Flambeau utilizes the latest technologies in order to provide its customers with high quality, precisely engineered products. Engineers with Flambeau Technology Center (FTC) in Baraboo, Wisconsin, utilize a state-of-the-art 3D scanner by Hexagon® Manufacturing Intelligence that assists Flambeau in maintaining its high standards of excellence for its products and services. The RS6 scanner […]

Our Work in Action

Our Engineering and Manufacturing Projects

Automotive Fuel Tanks

HVAC Air Ducts

Septic Tanks

tanks designed to meet specific environmental regulations and customer requirements…